-

World Leading In Surface Chemistry Instrument!

→ ADSA-RealDrop method for measuring contact angle without Axisymmetric Shape

→ Only Contact Angle meter with DSA-RealDrop method is real contact angle meter

→ Meter Using circle fitting or ellipse or tangent Is just goniometer not contact angle meter

→ World leading 3D contact angle sample stage and 3D contact angle microscope lens

→ World leading dynamic interfacial tensiometer by Wilhelmy plate method

-

Inventor of 3D Contact Angle Meter In the World!

→ Innovative development from 2D to 3D contact angle

→ New Application for contact angle hysteresis phenomenon

→ Improving the measuring accuracy of contac angle and surface free energy

→ Analysis of Heterogeneity of solid surface by 3D contact angle tool

-

We Share You More Than a Meter!

→ We are willing to share you our research and measuring experience

→ We can make special function or accessories for you to meet your application

→ More than 200 videos for solution of measuring contact angle or surface tension

→ Professional experts to give you recommend for contact angle meter or surface tensiometer

→ We have provided more than 1000 machines all over the world

-

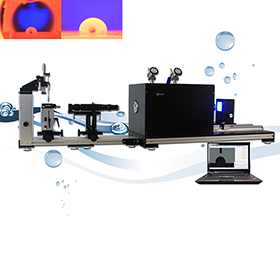

World Leading Drop Shape Analysis System C60

→ Parallel background light and telecentric lens

→ Automatic rotating stage with resolution of 0.001° for dynamic contact angle

→ 3 syringe system for automatic surface free energy measurement

→ World Leading software CAST3.0 with ADSA-RealDrop special for contact angle and surface tension

→ Modular design idea:3D contact angle, scalable extensibility, adhesive force by weight method

-

Ultra High Pressure Spinning Drop Tensiometer TX500HP

→ Max temperature 200℃, Max pressure 70MPa

→ Drop shape analysis system by spinning drop method

→ Lowest value of interfacial tension can reach 10-6mN/m under pressure conditions

→ Patent technology in China and more for your applications in the oil field

-

Most Popular Contact Angle Meter SL200K

→ We are the first one provide the rotating stage for standard part

→ We are the first one using multi-tilted sample stage controlled by micrometer to level the surface

→ World Leading software CAST3.0 provides ADSA-RealDrop for contact angle and surface tension

→ We are the first one using blue light LED and Color camera for measuring contact angle

→ Max 4 syringe system for measuring 8 contact angle values in one captured image

-

World Fast speed dynamic Surface Tensiometer A80

→ Adopt analytical balance with speed 92datas/second

→ Based on Young-Laplace equation correcting method by A.W.Neumann

→ Positioning Stage for sample stage using Grinding screw with 0.5mm screw pitch

→ Benefit from correcting contact angle and buoyancy, We are the only one can measure dynamic interface tension

→ Measuring density under condition of high pressure and temperature

-

Ultra High Pressure Contact Angle Meter SL200HP

→ Provides storage tank for crude oil and piston sampling tank

→ Provides high pressure system for air such as CO2 or methane

→ Automatic constant high pressure system to provide a stabilized condition

→ Interfacial Rheometer using servo motor under high pressure and temperature condition

→ World leading software CAST3.0 using ADSA-RealDrop for contact angle, surface tension and density

- Instruments for Interface chem.

- Real CAM

- 3D contact angle meter

- World Leading

- Contact angle meter

- High pressure Spinning drop

- Contact angle meter SL200K

- Surface tension meter A80

- High pressure Conact angle meter

- Demo Video for contact angle meter